IIoT Solutions

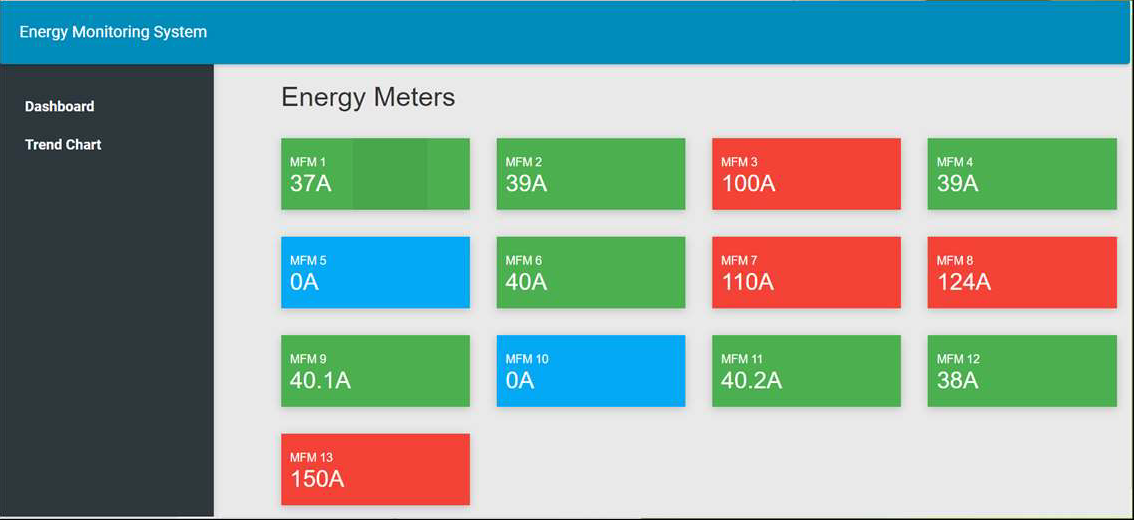

Current Monitoring System

Project Overview

- This system is installed in Utility Electrical department of Metal Plant

- Real time current monitoring from Server Room is easier because of our

- system & its software

- High Current, Low Current, Trip alarm On screen notifications

- Trend Chart for Motor Current activity

- Historic Data Report for One Year

- Communication of ABB Relay based on IEC61850 to our Software Platform.

Chemical Level Monitoring using IIoT Gateways

Advantages of Solution

- Optimize Demand – Supply

- Reduce Human Resource Requirement

- Trace leaks in Real-time

- Monitor hazardous chemical usage

- Monitor Propane tank

- Reduce manual operations

- Keep the costs low

Objectives

- With this Gateway, you can keep track of exact levels in your tanks at any time. See if levels are increasing or decreasing and get alarms whenever certain thresholds are reached. Streamline your service operations by refilling/emptying only when needed.

- The communication gateway connects to the tank level sensor using a serial, Ethernet or I/O connection. The gateway sends information via the Internet or the cellular network (GSM/GPRS/3G) to the cloud-based data center.

- The data is encrypted both to and from the server.

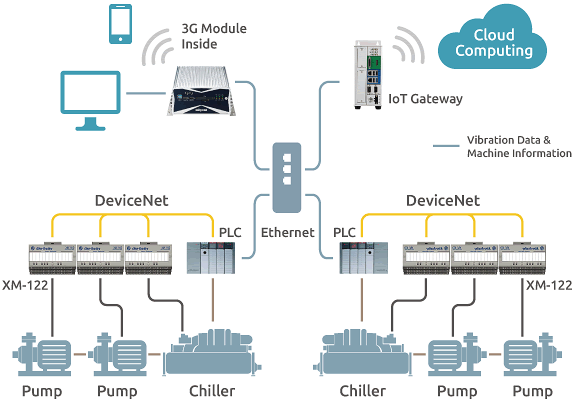

Predictive Maintanance IIoT Solution

Predictive Maintenance Solution

In the practice of predictive maintenance machine vibration is detected by sensors and processed by the Fast Fourier Transform Time-Frequency Conversion. The processed data, formatted into spectrum, waterfall, orbit, and overall wave forms, is then collected by ORRIS IIoT Gateway and sent to the predictive maintenance SCADA ORRIS. With the seamless integration to cloud services where mathematical modules are applied, health status of industrial machinery including power generators, chillers, pumps and others can be closely monitored and analyzed to reduce unexpected downtime (see figure).

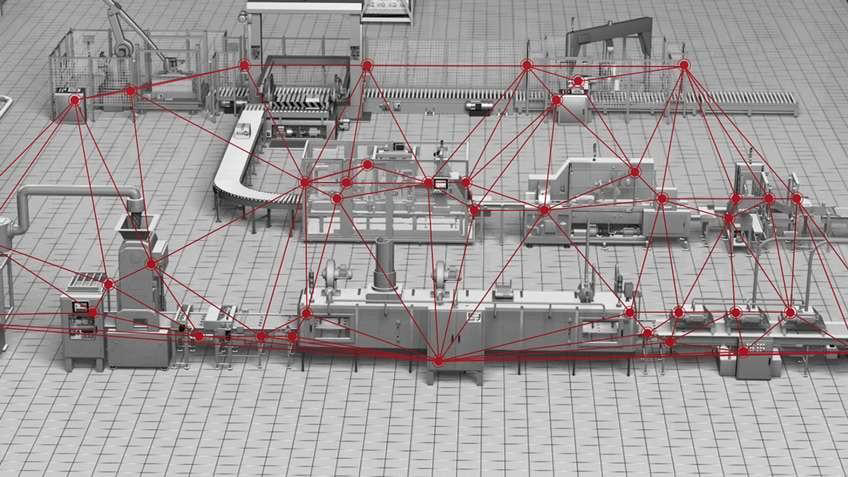

IoT Motor Monitoring for Smart Factory

ADVANTAGES

- Reduction in Human Errors

- Improving Quality Consistency

- Reducing Production Cost

- Guaranteed Productivity Gains

- Flexibility in Customization

- Faster Production

OPERATIONS

Lathe Machines are interlinked with Wi-Fi Gateway for fetching real time data of Motor. Here we are monitoring

real time records of Motor Current, Voltage and Temperature using our IIoT gateway.

This real time data is collecting by our gateway and passing to local server or cloud based server using Wi-Fi. Our Software is designed in such way that Management is able to see real time records of connected machinery of their plant. This gives you the entire details of Motor in given parameters.

Get In Touch

Address

759/70, Vatsala Bhuvan, Lane No.1, Prabhat Road, Deccan Gymkhana, Pune-411004, Maharashtara, India.

Phone

+91 7499103679

SALES@ORRIS-OVERSEAS.COM

ORRIS.SALES@GMAIL.COM